Extruding Plastic Foams to Meet Today’s Market Needs

Package Includes

6 months access to Course Recording, Presentation Slides, Q&A Transcript

Course Description

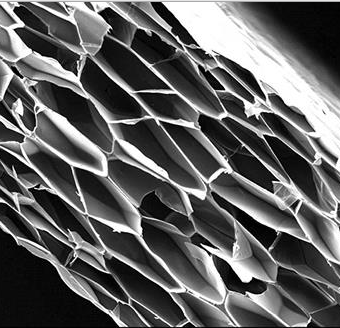

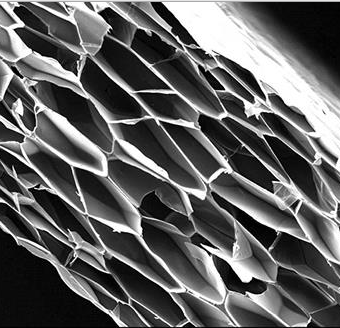

Successfully extrude plastic foams that comply with existing and new application demands (e.g., energy-efficient buildings, lightweight automotive, packaging) by employing the latest practices in the evolved art of foam extrusion.

Learn to achieve desired foam characteristics by choosing the right raw materials (e.g., foaming agents, resins), equipment, and processing conditions. Also, get tips to troubleshoot foaming issues (e.g., cell collapse, coalescence, uncontrolled foam structure).

Ana Espert

GCR GroupWhy should you view this course?

Who should join this course?

-

This course is suitable for beginner level proficiency

Beginner

Course Outline