How to Show Improved Wetting of Lubricants during Polymer Processing

Chapters

Welcome

0:0Few Words About Paul Seemuth

1:24Principle of Wetting of Polymer

3:41The Ideal Case

6:12How to Determine if a Material Will Wet a Surface

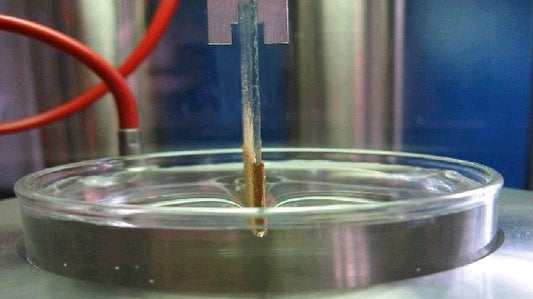

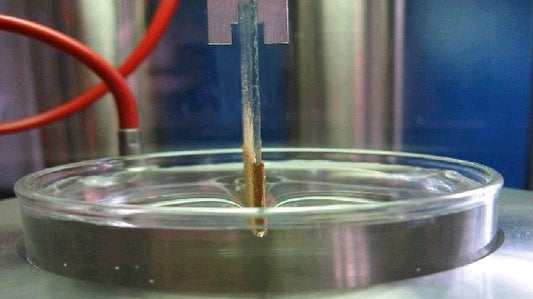

6:58The du Nouy Ring Method

7:40The Wilhemy plate method

8:50The Sessile Drop method

10:7The Dynamic Sessile Drop method

12:0The Modified Simple Sessile Drop method

12:52Summary and Conclusion

18:59

Paul Seemuth

Sign-up and Track all your learning now!

Free Course Details

In almost any polymer process, we use lubricants so the plastic parts are more resistant to wear & tear. But surface damage and poor quality issues can appear despite adding lubricants. Well, this is generally the results of a poor wetting of lubricants during polymer processing. It can lead you to an increase in process issues, process stops, reject rate and other quality concerns.

Watch this tutorial and learn the ways to determine if a material will wet a substrate’s surface. Our specialist Paul Seemuth will share a fast screening test to select an improved lubricant package.