Twin Screw Extrusion Essentials: From Design to Troubleshooting

Courses Included in this Bundle

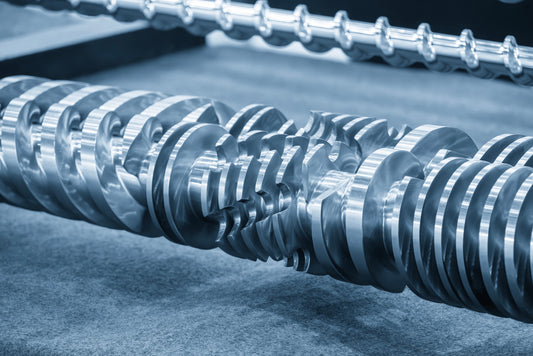

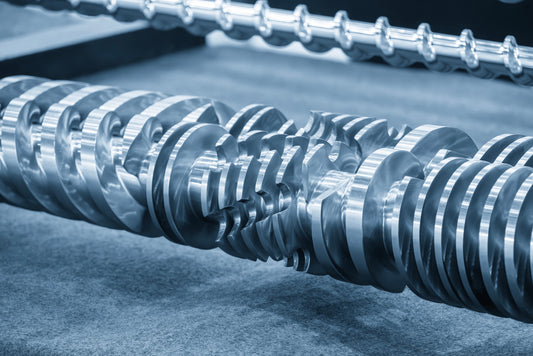

Introduction to Twin Screw Configuration and Design

By Luis Roca Recorded on: 09 Jul 25Package Includes

6 months access to Course Recording, Presentation Slides, Q&A Transcript

Bundle Description

Twin screw extrusion is a key processing technology for plastics, additives, and specialty compounds. However, achieving consistent quality and high efficiency isn’t always straightforward. Issues like poor dispersion, material degradation, inconsistent melt flow, and feeding inefficiencies can lead to defects, waste, and costly downtime.

This Twin Screw Extrusion Essentials bundle provides everything you need to optimize your extrusion process. You’ll gain:

- A solid understanding of screw design and configuration to enhance material flow.

- Practical techniques to optimize processing conditions for better performance.

- Proven troubleshooting strategies to solve common extrusion challenges quickly and effectively.

Whether you're scaling production, fine-tuning operations, or resolving inefficiencies, this bundle equips you with the expert knowledge and tools to ensure smooth, high-quality, and efficient extrusion processes.

Why should you view this bundle ?

This bundle is meant for ?

-

This course is suitable for intermediate level proficiency

Intermediate

What you can achieve with this bundle

Complete your Learning with this bundle

Course 1

Twin Screw Extrusion: Troubleshooting Compounding Challenges

By Luis RocaSee Course Summary

Troubleshoot your compounding issues (low productivity rate, contaminants, melt fracture...) with twin-screw extruders by knowing how to adjust processing parameters as per your material or batch-size.

Expert Luis Roca will help you correlate compounding instabilities with the interactions between extruder configuration, process parameters and response variables (residence time, specific mechanical energy).

Course Outline

- Module 01:

- Module 02:

- Module 03:

- Module 04:

- Module 05:

Course 2

Introduction to Twin Screw Configuration and Design

By Luis RocaSee Course Summary

Overcome your polymer compounding challenges (melt disturbance, uneven material thickness, surging…) by unravelling the underlying science behind twin screw extruder configuration and design.

In this course industry expert Luis Roca will explain how different element designs function to ensure proper distribution & dispersion of ingredients & materials. He will also lay focus on unit operations like polymer melting, mixing, devolatilization... to help you achieve high quality & productivity.

Course Outline

- Module 01:

- Module 02:

- Module 03:

- Module 04:

- Module 05:

- Module 06: