Technical Problem Solving

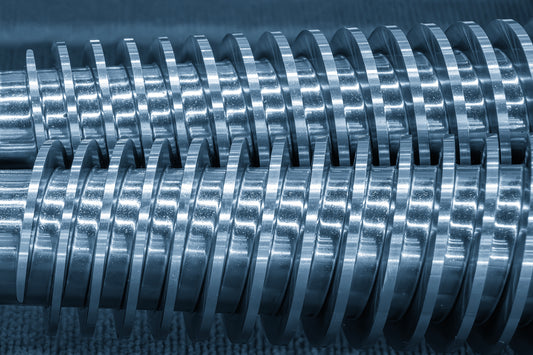

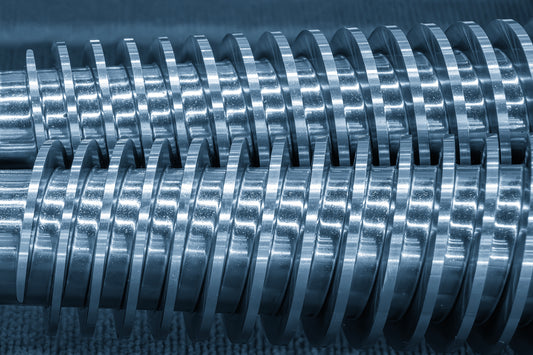

Twin Screw Extrusion: Troubleshooting Compounding Challenges

Language: English

Length: 90 min

Course Description

Troubleshoot your compounding issues (low productivity rate, contaminants, melt fracture...) with twin-screw extruders by knowing how to adjust processing parameters as per your material or batch-size.

Expert Luis Roca will help you correlate compounding instabilities with the interactions between extruder configuration, process parameters and response variables (residence time, specific mechanical energy).

Expert Luis Roca will help you correlate compounding instabilities with the interactions between extruder configuration, process parameters and response variables (residence time, specific mechanical energy).

Luis Roca

AIMPLAS

0 courses

See Tutor Profile

Why should you view this course?

Who should join this course?

-

This course is suitable for intermediate level proficiency

Intermediate

Questions you will be able to answer after this course:

Course Outline

30 min Q & As for this course

Share this Course

Share this Course

https://courses.specialchem.com/products/twin-screw-extrusion-troubleshooting-compounding-challenges